|

| Project On Classroom Attendance System Using Radio Frequency Identification RFID |

ABSTRACT

Radio

frequency identification (RFID) is a technology that uses radio waves to

transfer data from an electronic tag, called RFID tag, attached to an object,

through a reader for the purpose of identifying and tracking the object. The

class management system provides the functionalities of the overall system such

as displaying ID tag transaction, recording attendance and other minor

functions. The tools used for achieving the system are assembly language (the

programming language for the microcontroller AT89C51), the Micro Integrated

Development Environment (MIDE) used is called MIDE asm-51 (this is the

environment where the assembly language was written, built in order to generate

the .hex file for simulating the system and burning the microcontroller) and

other physical components like reset button, 40 pin IC socket, ribbon cable and

vero board. The methodology used in system is strictly based on Rapid

Application Prototyping. The system comprises of the RFID module reader

typically contains a module (transmitter and Receiver), a control unit, a

coupling element (antenna) and RFID tags. The System could be able to store the

student’s data in the AT89C51 microcontroller.

It reduces and eliminates paper

based work, saving the time of attendance

call; authenticate

attendance with no proxy

attendance.

CHAPTER ONE

INTRODUCTION

1.1 Background

of the study

Classroom

Attendance Management System (CAMS) is the easiest way to assist the faculty

and the lecturer for this time-consuming process. The most common means of

tracking student attendance in the classroom is by enforcing the students to

manually sign the attendance sheet, which is normally passed around the

classroom while the lecturer is conducting the lecture. For instance, lecturers

with a large class may find the hassle of having the attendance sheet being passed

around the class and the manual signing of attendance by students are

burdensome and most likely distract them from teaching and getting full

attention from the students .Besides, as the attendance sheet is passed around

the class, some students may accidentally or purposely sign another student's

name. The first case leads to a student missing out their name, while the

latter leads to a false attendance record. Another issue of having the

attendance record in a hardcopy Form is that a lecturer may lose the attendance

sheet. In terms of attendance analysis, the lecturer also has to perform manual

computation to obtain the students’ attendance percentage, which normally

consume a lot of time.

RFID (Radio frequency identification) is a new technology that incorporates the use

of electromagnetic or electrostatic coupling in the radio frequency portion of

the electromagnetic spectrum to uniquely identify an object, animal, or person. Radio frequency identification can be a powerful tool in helping to manage student‘s

attendance throughout the working school day and also enhance classroom

security. RFID technology has been applied to solve problems where it is

necessary to take automatically record the movements and locations of students

in a classroom of school/university environment. RFID, which is an automatic

identification technology used for retrieving from or storing data on to RFID Tags without any physical contact.

Recent

advancements in chip manufacturing technology are making RFID practical for new

applications and settings, particularly consumer item level tagging. These

advancements have the potential to revolutionize supply-chain management,

inventory control, and logistics. At its most basic, RFID systems consist of

small transponders, or tags, attached

to physical objects. RFID tags may soon become the most pervasive microchip in

history. An RFID system primarily comprises of RFID Tags, RFID Reader, and

Middleware. RFID Tags are uniquely and universally identified by an

identification sequence, governed by the rubrics of EPC global Tag Data

Standard. A tag can either be passively activated by an RFID reader or it can

actively transmit RF signals to the reader. When wirelessly interrogated by RFID transceivers, or readers,

tags respond with some identifying information that may be associated with

arbitrary data records. Thus, RFID systems are one type of automatic

identification system, similar to optical bar codes.

There

are many kinds of RFID systems used in different applications and settings.

These systems have different power sources, operating frequencies, and

functionalities. The properties and regulatory restrictions of a particular

RFID system will determine its manufacturing costs, physical specifications,

and performance. Some of the most familiar RFID applications are item-level

tagging with electronic product codes,

proximity cards for physical access control, and contact-less payment systems.

Many more applications will become economical in the coming years.

While RFID adoption yields many efficiency benefits, it still faces several hurdles.

Besides the typical implementation challenges faced in any information

technology system and economic barriers, there are major concerns over security

and privacy in RFID systems.

1.2 Problem

Definition

Most

of the universities still use old method to take attendance student by giving

attendance sheet to student and student only needs to sign that paper. By use

this method, many students will cheat by asking their friends to help them to

sign their attendance if they absent. With this method, lecturers have to

analyze and record the attendance list manually to know who absent and come to

class. If the attendance sheet lost, the lecturers have to take attendance

again and this will give opportunity to students to cheat their attendance.

This would impose the lecturer and data that given also inaccurate.

The

attendance of all students present in a given class was recorded. To carry out

this registration, each lecturer has an attendance register that must be filled

in for every class held.

At the beginning of each lesson the lecturer

was required to fill in the attendance sheet with all the information

concerning the lesson. After that, the attendance sheet handed out so that all students

will sign the sheet. When all students have signed, the lecturer collects the

sheet and checks the attendance of each student. The purpose of the attendance

sheet is to verify whether the student has already exceeded the maximum number

of absences allowed for each subject. This procedure, besides being troublesome

for lecturer, also affects students as time is expended on signing, verifying

and submitting the attendance sheet manually. Therefore, a system that can

manage and help the lecturers to take attendance easily has to be developed.

This system must be created based on UMP regulation for attendance contains

information about all students from a lecturers section. The system can be

easily accessed by the lecturers. This system must be able to manipulate and

manage the data of the student attendance so that the lecturers do not have to

analyze the student attendance manually. They only have to transfer the data,

and the system will analyze all the data automatically. Moreover, these loading

processes will have to be carried out every semester.

1.3

Aims of

the Research

The aim of this system is to transform

manual management

system to automatic system by the Radio frequency identification technology. The Student

Attendance System using Radio frequency identification technology will significantly improve the current manual process of student attendance recording and tracking system, especially in a university environment. The

system promotes a fully-automated approach in capturing the student attendance and

monitoring the student in the university campus. And also

to uniquely identify individual students

based on their unique tag identifiers.

Objectives

Radio frequency identification (RFID) based attendance system is one of the solutions to address the above mentioned problems.

·

As a system that can automatically capture

student’s attendance by flashing their student card at the RFID reader

or passing under the reader without physical site of contact,

it reduces and eliminates paper

based work, saving the time of attendance

call; authenticate

attendance with no proxy

attendance.

·

Secured Radio frequency identification (RFID) based attendance system will be able to provide security and privacy in such a way that the tags and

the product codes will not be compromised.

These objectives

will lead to an improved students’ attendance to classes and their

performance.

1.4 Significance

of the Study

This

project will be beneficial to lectures and administrators of colleges and

university around the world with large number of students per class and still

uses the manual method of taking students class attendance by roll or signing

attendance sheet.

1.5 SCOPE

OF THE STUDY

RFID technology has a widened horizon as it transcends into an era of emerging applications. This research

work will focus on the design

and construction of an attendance management system using RFID technology to monitor

the attendance for a group of

students.

The design will incorporate both physical security for the class environment

and internal security and privacy for proper student authentication.

1.6 LIMITATIONS

The major limitations associated with Classroom attendance System using RFID are:

·

No RFID standard has been set yet. (The

Auto-ID center has worked with standard bodies Uniform Code Council and EAN

International to come up with electronic product code, but it is not yet

considered a standard).

·

The demand should also drive down the price.

(Wal-Mart says that a need for one billion RFID tags should drive down the price to five

dollars each.)

·

Physical limitations like reading through

liquid or metals still exist. Accurate read rates on some items can be

very low. Nylon conveyor belts and other RFs can disrupt the tag

transmissions in warehouses increase in expenses - the suppliers will have

to equip their warehouses and transport vehicles with readers. These readers

have to be connected to the computer networks for exchange of information. All

these mean additional costs related to hiring technical consultants and

additional hardware.

·

In the tie up with IBM Global Services that has

resulted in deployment of RFID equipment in grocery sections of seven pilot In

the tie up with IBM Global Services that has resulted in deployment of RFID equipment in grocery sections of seven pilot Wal-Mart stores, IBM consultants

have encountered interference from equipment such as handheld walkie-talkies,

forklifts, and other devices typically found in distribution facilities. Cell

phone towers located near the premises, which transmit at the high end of the

frequency band, sometimes leak unwanted radio waves into RFID readers.

1.7 DEFINITION OF TERMS

Antennae: They are the conduits between the tag

and the transceiver, which controls the system’s data acquisition and

communication.

Bar Code: A standard method of identifying

items based on lines of varying widths and spacing that are visually read by a

scanner. The UPC bar code standard provides a way of identifying manufacturers

and product categories. Other types of bar codes are used for shipping and

other kinds of item identification. See also Scanner and Universal Product Code

(UPC).

Controller:

It is the interface between one or more antenna and the device requesting

information from or writing information to the RF tags.

Data

Transfer Rate: The rate at which

data are transferred between the reader and a tag, generally measured in bits

per second (bps).

Tag: A combination of a microchip and

antenna that can be programmed with information to identify items and transmit

that information to a receiver. Some tags can also receive new information,

such as location information during shipment.

Reader/Writer: A device that can both retrieve

information from a tag and write information to a tag. Many applications require that new data or revisions to data

already in the tag, be entered into the tag, while it remains attached to its

object. The ability to read from and write data to the tag while attached to

its object is called in-use programming. Tags with this capability are said to

be re-programmable and are called read/write tags, memory cards or memory

modules

Radio-frequency

identification (RFID): It

is the wireless non-contact use of radio-frequency electromagnetic fields to

transfer data, for the purposes of automatically identifying and tracking tags

attached to objects.

Scanner: A device that reads bar codes. The

antenna's, transmitter (or exciter) and receiver electronics integrated in a

single package called the scanner. They may be combined with additional digital

electronics including a microprocessor in a package called a reader.

1.8 ORGANIZATION OF THE

CHAPTERS

The work was

organized in chapters so as to be

conducive for the reader when reading, it was arranged as thus: Chapter one-

Introduction which consist of the Background of the study, Problem definition,

Aim and objectives of the study, Significance of the study, Scope of the study,

Limitations, Organization of work and Definition of terms, Chapter Two-

Literature review which consists of the History of Radio frequency identification (RFID) and Related Literatures, Chapter Three- System analysis

which consist of Methodology/Data collection methods, system requirements

consist of Hardware requirements, Software Requirements. Functional

Requirements and Non-functional Requirement. Chapter Four- System Design which

consist of Program design, Input Design, Output Design and Test Plan. Chapter

five-System implementation which consist of testing, User testing and

documentation which consist of user manual, installation guide and

troubleshooting. Chapter six- Conclusion which consist of summary, evaluation,

problem encountered and lesson learnt.

CHAPTER

TWO

LITERATURE REVIEW

2.1 Historical

Development of RFID

In

1986, the modern era of neural networks was ushered in by the derivation of

back propagation. In the short ten years since the rewriting of parallel

distributed processing (Rumelhart and McClelland, 1986) an enormous amount

of literature has been written on the topic of neural networks. Because neural

networks are applied to such a wide variety of subjects, it is very difficult

to absorb the wealth of available material. A brief history of neural networks

has been written to give an understanding of where the evolution of neural

networks started. A detailed review has also been written for this study of the

feed-forward neural network and the back propagation algorithm. Papers on

various topics related to this study are detailed to establish the need for the

proposed work in this study. However, ten years is not a very long time for

research, so no one book has distinguished itself as the leading authority in

the area of neural networks.

RFID is not a new technology despite rapidly growing interest in RFID technology in

recent years. The concept of the technology dates to “the mid to late 1940s,

following on from technological developments in the 1930s and the development

of radar during World War II” (Hodges and McFarlane, 2005) . In the 1950s,

several technologies related to RFID technology were developed. One prominent

example is the “identification friend or foe (IFF)” system for aircraft which

is a long-range transponder system. An active IFF system was first developed

for British aircraft whereby each aircraft was equipped with a transponder.

When radar stations emitted signals from the ground, the aircraft transmitted a

signal back to identify itself as friendly (RFID journal, 2007) . The first commercial applications

emerged in the 1960s and 1970s. The electronic article surveillance (EAS)

equipment was developed by new companies such as Sensormatic and Checkpoints (Landt and Catlin, 2001) to prevent theft of

goods at the point of sale. This system is currently in widespread use. With

generally a 1-bit transponder, it is the most basic use. The data is sufficient

to tell the reader whether a transponder is located in a certain area or not (Finkenzeller, 2006) . Overall, this

period was characterized by important further development of RFID technology.

Research focused on applications for animal tracking, vehicle tracking, car

keys, as well as process automation in production facilities (Landt and Catlin, 2005) . Besides the

development of these commercial applications, governments also began the

development of RFID systems in the 1970s. For example, the US Department of

Agriculture spurred the development of animal tracking and the US Department of

Energy promoted the development of a system to track nuclear materials (RFID Journal, 2007) which was put in place in the mid-1980s. In the 1980s, the

“commercial exploitation of RFID started to increase, led initially by small

companies” (Hodges and McFarlane, 2005). An important aspect for the expansion

of the technology was the development of the Personal Computer (PC)

facilitating data management. Whereas the exploitation of RFID was a common

point in different countries, the interest in special fields of application

diverged. The main interests in the US were for applications including access

control of persons and transportation.

Countries

were mainly interested in toll collection systems and industrial applications

as well as short-range systems for the tracking of animals (Landt and Catlin, 2001) . Overall, from a

technological point of view, applications developed to this point were mainly

operating at low-frequency and high–frequency ranges. In the early 1990s,

applications operating at ultra-high frequency (UHF) emerged (RFID journal,

2007). These systems attained a higher read range and faster data transmission

than systems operating at lower frequency ranges. The very first pilot projects

started in the retail sector for the tracking of consumer goods along the

supply chain. However, due to low volumes, these RFID systems were expensive (RFID Journal, 2007). A further obstacle to widespread use was that applications

to this date were niche applications. As a consequence, a large number of

proprietary systems were developed which were incompatible with each other

(Landt and Catlin, 2001). The development of standards was thus crucial both

for price decline and the use of RFID technology beyond niche applications.

Standardisation activities emerged in the late 1990s. The International

Organisation for Standardisation (ISO) developed several standards in the field

of RFID. One example is the ISO 18000 series which defines the air interface

for different frequencies, i.e. how readers and tags of an RFID system

communicate with each other. Furthermore, in 1999, the Auto-ID Center at the

Massachusetts Institute of Technology (MIT) was established “to develop an open

standard architecture for creating a seamless global network of physical

objects” (Auto-ID Labs, 2006). It was initially funded by the Uniform Code

Council, European Article Numbering (EAN) International and industry. By the

year 2003, the Center was supported by over 100 user companies, key RFID suppliers and the US Department of Defense and a federation of Auto-ID research

institutes was created. Specifications developed by the Auto-ID Center focused

on low cost tags for goods with the aim of tracking them along the supply

chain. The results of the standardisation activities include two air interface

specifications, the Electronic Product Code (EPC) numbering scheme as well as a

network architecture (RFID Journal, 2007). These specifications were

passed to EPC global for commercialisation purposes, besides standardisation

activities, the 1990s were furthermore characterised by an increased

commercialisation of RFID systems. According to Landt and Catlin (2001),

electronic toll collection systems were widely deployed both in the United

States and Europe. For example, different regional toll agencies in the

Northeast of the United States developed a regionally compatible toll system.

Further important implementation projects included applications such as the

tagging of over three (3) million rail cars in the United States, access

control applications (e.g. company badges and ski passes) as well as

applications along the supply chains of companies. For example, in the late

1990s, European car manufacturers started RFID projects for asset tracking and

tracking of parts along their internal supply chains. In addition, an RFID–based immobiliser system for cars was commercialised in the mid-1990s

which authenticate car keys and is in wide use. With the broader deployment of

scheme as well as a network architecture (RFID Journal, 2007). These

specifications were passed to EPC global for commercialisation purposes,

besides standardisation activities, the 1990s were furthermore characterised by

an increased commercialisation of RFID systems. According to Landt and Catlin

(2001), electronic toll collection systems were widely deployed both in the

United States and Europe. For example, different regional toll agencies in the

Northeast of the United States developed a regionally compatible toll system.

Further important implementation projects included applications such as the

tagging of over three (3) million rail cars in the United States, access

control applications (e.g. company badges and ski passes) as well as

applications along the supply chains of companies. For example, in the late

1990s, European car manufacturers started RFID projects for asset tracking and

tracking of parts along their internal supply chains. In addition, an RFID–based immobiliser system for cars was commercialised in the mid-1990s

which authenticate car keys and is in wide use. With the broader deployment of

these applications, multiple use tags arose e.g. for toll collection,

access control and gated community access (Landt and Catlin, 2001).

The

beginning of the 21st century is marked by growing interest of industry,

government and the media in RFID technology further technical development, and

first round of standards harmonization.

In addition, the public sector has important RFID implementation projects e.g. in the areas of defense, health,

e-passports and identity cards. Overall, the range of different applications is

broadening at a rapid pace and new applications which also integrate other

technologies such as sensor technology are emerging.

2.1.1 Related Literatures

The

potential in terms of benefits and performance enhancements appear to be

promising for companies in a wide array of industries. Many who have already

embraced and integrated RFID into current business processes have discovered

and gained a number of advantages including a competitive edge towards other

actors.

It

is relevant to understand how RFID have influenced and affected others. In fact

it can be considered crucial for most business managers to understand the

impact of RFID on supply chains as a whole. The case studies described

hereafter serve to provide a brief understanding of how RFID have been used by

other firms and what benefits the technology has provided.

2.1.1.1 United States Defense logistics

The

US. Government Accountability Office (GAO) together with the Department of

Defense (DOD) is investigating how RFID can be implemented in supply chains

throughout the various defense-branches. Currently, active tags are being used

to track large and bulky assets overseas. However, the plan is to invest over

$500 million in a full implementation of passive technology throughout the

supply chains.

The

DOD estimates that RFID technologies can reduce system loss, waste, and theft.

By allowing for hands-off identification of assets, the DOD can develop a more

transparent inventory management system and increase visibility. Passive RFID technology is described by the DOD as ‘promising’, both for logistics

operations in the military, as well as commercially. (US. GAO, 2005)

2.1.1.2 RFID receiving systems at Paramount farms

2.1.1.2 RFID receiving systems at Paramount farms

Paramount

farms, one of the largest suppliers of pistachios worldwide, implemented RFID on the receiver end of the supply chain in order to increase goods visibility.

Trailers from suppliers were tagged and the Paramount facility was equipped

with readers. The system allowed for automatic data entry, ensured accuracy and

a more effective logistics process. Before implementing RFID, employees handled

data entry, and goods check manually; a time consuming process, sometimes resulting

in errors.

Paramount

noted that RFID speeded up the goods receiving process significantly. Loading

times were shortened with up to 60%, and trailer usage was reduced with about

30%, enabling the company to meet increased production goals without investing

in new assets or increasing workforce. (Barua, Deeoa and Andrew, 2006) .

2.2.3 Lahey Clinic Managing Healthcare Assets Using RFID

Lahey

clinic Medical Centre, a medium sized medical facility in Boston has some 1,500

pieces of movable medical equipment. The hospital implemented an RFID based

tracking system in order to keep track of its assets. Equipment was tagged with

passive reflectors and readers were installed at key points throughout the

facility.

The

hospital noted significant improvements in tracking equipment throughout the

facility.

Staff

utilized time more effectively, in that less time had to spend finding

equipment. Also, the increased effectiveness reduced problems with overstocking

and allowed for increased asset utilization and use of investment. Finally,

equipment maintenance routines were optimized in that the asset tracking system

of the hospital was linked with the database of its providers, allowing for

responsive maintenance. (Barua et.al, 2006) .

2.1.1.1Radio frequency identification (RFID)

RFID, which stands for Radio frequency identification, is an automatic identification technology

used for retrieving from or storing data on to RFID Tags without any

physical contact.

It is a technology that is used to collect information

automatically by radio frequency data communication between mobile objects

and an RFID reader, to identify, categorize and track the

mobile objects. According to Lim et al (2009),

an RFID system primarily comprises of RFID Tags, RFID Reader, Middleware and a Backend

database. RFID Tags are uniquely and universally identified by an identification sequence, governed by the rubrics of EPC (Electronic product key) global Tag Data Standard. A tag can either be passively

activated by an RFID reader or it can actively transmit RF signals to the reader. The RFID reader, through its antenna, reads the information stored on these tags when it’s in its vicinity.

The reader, whose effective range is based on its operational frequency, is designed to operate at a certain frequency. The operational frequency of the reader ranges from 125 KHz–2.4 GHz. The

Middleware encompasses all those components that are

responsible for the transmission of germane information from the

reader to the backend management systems. The Middleware can include hardware components like cables and connectivity ports and embedded system software like Assembly language and embedded C that monitor and control the communication between

the hardware and the computer system. The Backend

database stores individual tag identifiers to uniquely identify the roles of each tag. The database stores

record entries pertaining to individual tags and its role in the system application.

The RFID system is interdependent on its core components

to achieve maximum efficiency and optimum performance of

the application. Due to its high degree of flexibility, the system can

be

easily adopted

for an

array of applications ranging from small scale inventory cabinets to multifarious and highly agile supply chain management systems. Although, the cost of incorporating this

technology

has restricted its outreach, the technology promises to have untapped potential.

2.1.1.2

Components of an RFID System

According to (Domdouzis et al. (2007), an RFID system consists of

various components

that are connected to one another by

a dedicated communication path

(see figure 1.2). The individual components are integrated into the system to implement the benefits of RFID solution.

The components is as follows:

·

Tags

Tags are objects that are attached to any product and use a unique sequence of characters to define them.

A tag consists of

a microchip that stores a unique sequence identifier that is

useful in identifying objects individually. The sequence

is a

numeric serial, which is stored in the RFID memory. The microchip includes minute circuitry and an embedded silicon chip. The tag

memory can be permanent or re-writable, which can be

re-programmed electronically by the reader multiple times. Tags are designed

specific to its applications and environment. For example, paper-thin tags are attached to books in a library management system.

Tags are available in various shapes and sizes (see figure 1.3). Tags that are initiated by the reader are known as Passive tags,

whilst those that do not require external initiation are called

Active tags. A Semi-Passive tag exists, which has the features of both Active and

Passive tags. Each tag type has its distinct characteristics, which are discussed in table 1. Tags are operable on Microwave (2.4 – 2.5 GHz), Ultra High Frequency

(UHF) (860 – 1500 MHz), High Frequency (HF) (13.56 MHz) and Low Frequency (LF) (125 kHz).

|

Tags can be classified according to their power and memory resources.

A tag’s memory is classified

as read-only, write−once,

read−many and rewritable. In terms of power supply, tags are classified

into three categories: passive, semi-

passive and active. Tags are called passive if they have no power supplies,

they receive their computational power from the electrical

field generated by the reader. Semi-passive tags

use a battery, but that battery is not for communication,

instead, it is used to run the internal circuitry, and the energy

of communication is provided by the reader. Active tags use

a battery for both communication and running the internal circuitry. EPC Class 1 Generation 2 (EPC-C1-GEN2) has served as the most popular

standard for passive tags. It supports on- chip

16-bit Pseudo-Random Number Generator (PRNG), and

a 16-bit cyclic redundancy Code (CRC) checksum is used

to detect errors in the transmitted

data.

·

Antenna

It is responsible for the transmission of

information between the reader and tag using radio waves. The antenna is the medium through which the tag and

reader communicate

with each

other. Antenna can

activate a passive tag and transfer data by emitting wireless impulse that has electromagnetic properties. They come in

following types:

o Stick antennas,

o Di-pole or multi-pole antennas,

o Beam-forming or phased-array

element antennas,

o Circular polarized,

o Gate

antennas,

o Patch antennas,

o Linear polarized,

o Adaptive antennas, and

o Omni

directional antennas

·

Reader

Reader is a scanning device

that uses the antenna to communicate to the tags that

are in

its vicinity.

It transmits signals at

a certain frequencies.

·

Middleware

Middleware is

embedded system program which is a communication interface

that control, interpret and process data being fed by

the readers into system. It takes into account all relevant ports of

communication and a software application to

represent this information. Middleware

is software based application which manages

the

readers, the data coming from the tags, and passes it to the backend database

system. Data from

tags

must go through software (middleware)

that can filter,

convert, correct and relay it to the appropriate systems. The middleware can reside on a reader or a

server

·

Backend database

A database is defined as an organized collection of data and tailored to system, the backend database primarily deals with the storage of relevant information recorded by the reader and communicated by the middleware..

2.1.1.3 Tag Selection

Every tag has an identifier that is used to uniquely identify it. A tag identifier format that is used across many

industrial sectors is the Electronic Product Code (EPC). The tag identifier format consists of four data fields.

The

parts are:

·

The Header, which

specifies

the

EPC type,

·

The EPC Manager

ID, which uniquely identifies the organization

that is responsible

for assigning the object class and serial number bits

(often the manufacturer of the item),

·

the Object Class, which identifies a class of objects, such as

a certain model of television

set, and

·

The Serial Number, which uniquely

describes the instance of that class of

objects (e.g., a particular television set).

Passive

tags do not have an internal

power source and

need to draw power from an RFID interrogator. The interrogator emits

electromagnetic waves that

induce a current in the tag's antenna and powers

the chip on the tag. When the power to the tag‘s chip passes the

minimum voltage threshold, the circuit turns on and the tag sends the information back to the reader. Semi-passive tags have

an on-board power source like active

tags but utilize it only

when they are interrogated by a reader. Communication on

these tags is carried out through reflection as it is

on passive tags. The onboard power helps these tags in

implementing more computationally

intensive

functionalities and enhancing

their read ranges. Active

tags contain their own battery that supplies

energy for both

to power the chip on the tag and boost the return signal. Compared to passive and

semi-passive tags, active

tags have wider

read

ranges,

larger

memory capacities

and

faster processing times.

This system uses the passive EPC Class 1 Gen 2 tag,

because they are small in size, they having

lighter weight,

any

person can carry easily like

smart card, cheap in cost, it can easily

be embedded in identity card, does not required battery

or

backup power.

The main advantage of EPC type coding is that it provides fast searching

(indexing) for tag‘s ID. It gives the quick result of searching tags ‘ID in

association to any conventional method such as sequence searching which is widely used in database system because it

has simple method. Assume one organization has two institutes

and each

institute has 600 students.

Each institute has two departments

and each department has 300 students. The total numbers of students are 1200 in an organization. All students

tag‘s ID are stored in database server. If

any

student’s tag ID is scanned by

the reader and it is send to server to search and mark the presence in appropriate subject’s class. Server will search all 1200

students tag‘s in worse case using linear searching

method.

If

we use indexing using EPC coding for tag ID then it

takes 2 (search for institute) + 2 (search for departments) + 300 (students id) = 304 search required in worse case.

2.1.1.4 Radio frequency identification (RFID) based attendance system

Radio frequency identification (RFID) based attendance system is one of the solutions to address this problem. According to Sumita et al (2013), Radio frequency identification (RFID) based attendance system is a system that can automatically capture student’s attendance by

flashing their student card at the RFID reader and by passing under an overhead Attendance Management System (AMS) is the easiest way to assist lecturers for this time-consuming process of

calling or recording attendance (Arulogun et

al, (2013)). The aim of this system is to read the tags in class room

and

not read the student away or outside from the class

room. For student attendance system, one can use both HF (3 MHz to 30 MHz [9]) or UHF (300 MHz to 3 GHz) readers and tags

but it is recommended that one uses UHF readers

because it can automatically identified students in the

classroom while in case of HF reader Student need to place his card near the RFID reader to register his/her presence. In the use of HF reader, student may

scan

the other student

card, but in UHF the reader automatically scan all tags

and

no chance for proxy attendance and latter

or at instance instructor/teacher can get the message in his

PC/laptop/mobile

about how many students that are present and absent. However UHF reader is expensive compare to

HF but UHF reader is well suited for this system.

The reader communicates with the RFIDtag via radio

waves and passes the information

in digital form to a computer system. The information

collected from the

tags is stored in the interrogator and later transferred to a data processing system. This RFID system uses Read-only

fixed mounted

interrogators reader (A

reader that can only read the information from the tag), however hand held reader can use where

class room is not fix.

The interrogator zone is the area around an interrogator within which it can successfully communicate with a

tag. Readers can attach to the system through any interface

(RS 232, USB, and Ethernet). In this system an interrogator

connected to the network using TCP/IP interface to the LAN

network easily because every campus

have the

facility of LAN infrastructure.

The server-less RFID scheme

that can be used in Radio frequency identification (RFID) based attendance system is shown in Figure 1.7. It

is composed of tags, readers and CA (Certification Agency.

According to Abdul Aziz Mohammed and Jyothi

Kameswari,

(2013), there are two phases in server less scheme:

·

initialization and

·

Authentication.

The mobile reader accesses the CA (Certification Agency) and downloads the AL (Access List) through the secure connection in an initialization phase. The mobile reader is generally a portable device such as notebook computer or smart phones. It might be stolen. Then AL is stored in it. It may wrongly be used to imitate the tags. Credentials of tag authentication are derived with the help of tags key and RID

(Reader Identification). It makes AL exclusively usable for the reader. But as a result, it is not possible for tag to create a valid request without the RID. In the authentication phase, the reader challenges a tag with RID, waiting for tags response with H (RID, Kt). The reader then searches its AL and finds the matched value to verify the Kt. It then identifies the TID (Tag

Identification). Server-less RFID architecture provides readers with the scalability. However, there are drawbacks in server-less authentication protocol;

·

They transmit RID in plaintext.

·

Searching through AL has complexity of O (N), where N denotes the number of tags.

·

Computational processes of searching and verifying are executed all by single personnel

portable device, which reduces the performance significantly.

CHAPTER 3

SYSTEMS ANALYSIS

3.1

METHODOLOGY

The

paper in question is an attendance system that monitors student attendance and

stored their data on a microcontroller. The mode of communication is wireless

using a radio frequency module. The primary purpose of an RFID technology in

the classroom attendance system is to detect the presence and absence of the student

data to be transmitted wirelessly by mobile device, called a tag, which is read

by an RFID reader and processed according to the programmed instructions on the

Microcontroller. RFID Based Attendance System development is divided into two

parts, hardware and software part. The hardware part consists of electronic

components connections. In this thesis, only the main components of classroom

Attendance System using RFID will be described, common components will not be

touched. For the software part, it discuss the development of microcontroller’s

program and printed circuit board design.

3.2

SYSTEM REQUIREMENTS

Under

the system requirement we have the hardware requirements and the software

requirements

3.2.1

HARDWARE REQUIREMENTS

Firstly,

the general components and process of RFID Based attendance system is outlined

before moving on to the connections of each component. This is done to assist

in determining the right electronic component for each process. The outline of

the system is shown below:

HARDWARE

DESCRIPTION

•

Microcontroller AT89C51

•

LCD (Liquid Crystal Display) (16*2)

• RFID Reader

• RFID Passive Tags-2 tags

•

40 and 16 pin IC socket

•

Regulator 7805

•

Capacitor 10µf

•

Connector

•

Max 232

•

Ribbon cable

•

Vero board dotted

•

Crystal Oscillator - 11.0592 MHz

•

Connecting wire

•

Soldering lead

•

Reset button

•

Resistor 10K/1K/470/100 ohm

•

Variable Resistor 10k

•

Transformer

MICROCONTROLLER

(AT89C51)

The

AT89C51 is a CMOS 8-bit microcomputer with 4K bytes of Flash programmable and

erasable read only memory (PEROM). The on-chip Flash allows the program

memory to be reprogrammed in-system or by ordinary nonvolatile memory

programmer. Atmel AT89C51 is a powerful microcomputer/microcontroller (as they

are used inter-changeably) which provides a highly-flexible and cost-effective

solution to many embedded control applications.

The Atmel AT89 series is an Intel 8051-compatible family of 8 bit microcontrollers (µCs) manufactured by the Atmel Corporation. Based on the Intel 8051 core, the AT89 series remains

very popular as general purpose microcontrollers, due to their industry

standard instruction set, and low unit cost. This allows a great amount of

legacy code to be reused without modification in new applications. While

considerably less powerful than the newer AT90 series of AVRRISC microcontrollers, new product development has continued

with the AT89 series for the aforementioned advantages. The

first integrated circuits and processors appeared which caused computers and

other products of electronics to drop down in price even more. They could be

bought everywhere. AT89C51/AT89C52 microcontroller is a cheap, universal

integrated circuit that could be programmed and used in any field of

electronics, device or wherever needed. More recently, the AT89 series as in table 1.1 has been augmented with

8051-cored special function microcontrollers, specifically in the areas of USB, I²C

(two wire interface), SPI and CAN bus controllers, MP3

decoders and hardware PWM.

RFID Tag

An RFID tag is comprised of a microchip containing

identifying information and an antenna that transmits this data wirelessly to a

reader. The RFID chip will contain a serialized identifier, or license plate

number, that uniquely identifies that item, similar to the bar codes system. A

key difference, however is that RFID tags have a higher data capacity than

their bar code counterparts. An RFID tag can be placed on individual items, cases or pallets for identification purposes, as well as on fixed

assets such as trailers, containers, totes, etc.

Radio frequency identification Reader

(RFID Reader)

RFID reader is a device used

to gather information from an RFID tag, which is used to track individual

objects. Radio waves are used to transfer data from the tag to a reader. RFID is a technology similar in theory to bar codes. However, the RFID tag does not

have to be scanned directly, nor does it require line-of-sight to a reader. The RFID tag it must be within the range of an RFID reader, which ranges from 3 to

300 feet, in order to be read. RFID technology allows several items to be

quickly scanned and enables fast identification of a particular product, even

when it is surrounded by several other items. RFID technology uses digital data

in an RFID tag, which is made up of integrated circuits containing a tiny

antenna for transferring information to an RFID transceiver. The majority of RFID tags contain at least an integrated circuit for modulating and

demodulating radio frequency and an antenna for transmitting and receiving

signals. Frequency ranges vary from low frequencies of 125 to 134 kHz and 140

to 148.5 kHz, and high frequencies of 850 to 950 MHz and 2.4 to 2.5 GHz.

Wavelengths in the 2.4 GHz range are limited because they can be absorbed by

water.

Liquid

Crystal Display (LCD):

Liquid

crystal display is the technology used for displays in notebook

and other smaller computers. Like light-emitting diode (LED) and gas-plasma

technologies, LCDs allow

displays to be much thinner than cathode ray tube (CRT) technology the

display unit consists of a 2*16 Liquid crystal display (LCD). This feature

enables the status of the system to be viewed on a screen, making the system user friendly. The model described here is for its low price and great

capabilities most frequently used in practice. It is based on the HD44780

microcontroller (Hitachi) and can display messages in two lines with 16

characters each. It displays all the letters of alphabet, Greek letters,

punctuation marks, mathematical symbols etc. In addition, it is possible to

display symbols made up by the user. Other useful features include automatic

message shift (left and right), cursor appearance, LED backlight etc.

TRANSFORMER:

A

transformer is an electrical device that transfers electrical energy between

two or more circuits through electromagnetic induction.

Regulator

7805:

Regulator

is a device for controlling the rate of working of machinery or for controlling

fluid flow, in particular a handle controlling the supply of steam to the

cylinders of a steam engine.

JUMPER

WIRE:

A

jump wire, is a short electrical

wire with

a solid tip at each end (or sometimes without them, simply "tinned"),

which is normally used to interconnect the components in a breadboard.

IC

SOCKET (16 PIN and 40 PIN):

An

IC socket, or integrated circuit socket, is used in

devices that contain an integrated

circuit. An IC socket is

used as a placeholder for IC

chips and is used in order to allow safe removal and insertion

of IC chips because IC chips may become damaged from heat

due to soldering.

Resistors:

Resistor

is a passive two-terminal electrical component that implements

electrical resistance as a circuit element. Resistors may be used to reduce current flow, and, at the same

time, may act to lower voltage levels within circuits.

Capacitor:

Capacitor

is a device used to store an electric charge, consisting of one or more pairs

of conductors separated by an insulator.

Crystals

Oscillator:

A

crystal oscillator is an

electronic oscillator circuit

that uses the mechanical resonance of a vibrating crystal of piezoelectric material to create an electrical signal

with a precise frequency. Oscillator circuit is

constructed between 18 and 19 th pin of the controller. It includes an

oscillator of 11.0592 MHz and two capacitors of 33pF

RIBBON

CABLE:

Ribbon

cable is also known as multi-wire planar cable, is a cable with many conducting

wires running parallel to each other on the same flat plane.

RESET

BUTTON

The 9th pin of microcontroller is

configured as RST pin, known as reset pin. It include a switch, a capacitor and

a resistor of 8.2k ohm. When switch is pressed RST pin gets connected to vcc

and the controller gets reset.

VERO BOARD

A Vero board is expertly

constructed using strips of copper clad on a top quality board featuring a grid

pattern of holes spaced 0.1" (or 2.54mm) apart. This design allows you to

solder almost any non-surface mount ICs, resistors, capacitors onto the Vero

board. With the Vero board you will receive both versatility and durability

allowing you the freedom and flexibility you crave!

MAX 232

The

MAX232 is an integrated circuit that converts signals from an RS-232 serial

port to signals suitable for use in TTL compatible digital logic circuits. The

MAX232 is a dual driver/receiver and typically converts the RX, TX, CTS and RTS

signals.

CONNECTOR

Connector

is a device used to join electrical circuit and are also referred to as

electrical connector

3.2.2

SOFTWARE REQUIREMENT

In

the development cycle of the system, decisions were made on the parts of the

system to be realized in the hardware design and the parts to be implemented in

software. The software is decomposed into modules so that each module can be

individually tested as a unit and debugged before the modules are integrated

and tested as a software system in order to ensure that the software design

meets its specification.

In

order for the system to function properly, the software requirements include

·

Programming language

called (assembly language): assembly language is a

general-purpose, imperative computer programming language, supporting

structured programming, lexical variable scope and recursion, while a static

type system prevents many unintended operations.

·

Proteus design suite 8

(Simulator): The Proteus Design Suite is an Electronic Design Automation

(EDA) tool including schematic capture, simulation and PCB Layout modules.

·

Programmer firmware

(pickit-3 version 3.1): is a type of software

that provides control, monitoring and data manipulation of engineered products

and systems.

3.4

FUNCTIONAL REQUIREMENT

The

system will be used from two different types of user that is the administrator

and the lecturer. The lecturer collaborates in student details in the system

while the admin will be responsible for the applications policies.

3.5

NON FUNCTIONAL REQUIREMENT

In

every software and hardware development exist except the functional requirement

and also sequence of non-functional requirement that played an important role

for the future of the system. The above application will run student attendance

system using the RFID Tag. The most important non- functional requirement in

this case is the security for the reason that lecturers exchange every

important information from student personal data.

User Friendly: - The

proposed system is user friendly because the retrieval and storing of data is

fast and data is maintained efficiently.

Availability:

The system is always available to users whenever operation is required during

the period of time.

Security:

The system is only used by lecturer. This means that it enables authorized

users.

Reliability: The system is readily reliable and

well working if constant electricity is available.

CHAPTER FOUR

SYSTEM

DESIGN

4.1 Program Design

Classroom Attendance system using RFID is a

highly specialized system that automate the whole system of students’

attendance registration using RFID. The major factors in designing a classroom

attendance system using RFID include: choosing the hardware and software

components and integrating both to work together, defining the system working

mode (verification or identification) and defining administration and

optimization policy .

4.1.1

Flow Chart

|

| Fig

4.1.1 flow chart design |

|

| Fig 4.1.2 Block diagram |

WORKING:

Each

student will hold a unique RFID tag and whenever student enters the RF receiver

zone the attendance will be registered automatically. The data which has been

received from the student’s unique card will be stored in the receiver buffer.

The data is then compared with the pre-assigned data in the database and based

on that the attendance is register to the particular student. The transmitter

will hold a unique address which will be transmitted by the means of radio frequency

to a particular region. The 2.3GHZ transponder will continuously respond to the

incoming data and will gather the data from the transmitter. The data will then

be stored in the microcontroller buffer. This unique id will be displayed in

the LCD screen. Then this data will be sent to the database

4.2

Input Design

The

input design of this system are electronics components used in building the

system design, the soldering components and the simulation of the design which

was design using proteus suite.

MICROCONTROLLER

(AT89C51)

The AT89C51 is a CMOS 8-bit

microcomputer with 4K bytes of Flash programmable and erasable read only memory

(PEROM). The on-chip Flash allows the program memory to be reprogrammed

in-system or by ordinary nonvolatile memory programmer. Atmel AT89C51 is a

powerful microcomputer/microcontroller (as they are used inter-changeably)

which provides a highly-flexible and cost-effective solution to many embedded

control applications.

|

| Fig.

1.1a Beck (1996) and 1.1b (live picture)

External architecture of AT89C51/AT89C52 microcontroller |

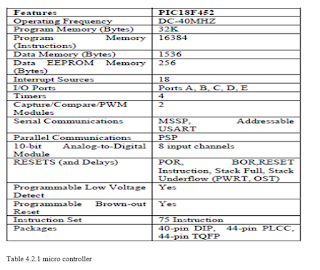

|

| Table

4.2.1 micro controller |

The Atmel AT89 series is an Intel 8051-compatible family of 8 bit microcontrollers (µCs) manufactured by the Atmel Corporation. Based on the Intel 8051 core, the AT89

series remains very popular as general purpose microcontrollers, due to their

industry standard instruction set, and low unit cost. This allows a great

amount of legacy code to be reused without modification in new applications.

While considerably less powerful than the newer AT90 series of AVRRISC microcontrollers, new product development has

continued with the AT89 series for the aforementioned advantages. The first integrated circuits and processors appeared which caused

computers and other products of electronics to drop down in price even more.

They could be bought everywhere. AT89C51/AT89C52 microcontroller is a cheap,

universal integrated circuit that could be programmed and used in any field of

electronics, device or wherever needed. More recently, the AT89 series as in table 1.1 has been augmented with

8051-cored special function microcontrollers, specifically in the areas of USB, I²C (two wire interface), SPI and CAN bus controllers, MP3 decoders and hardware PWM.

|

Fig 1.2 RFID TAG

|

An RFID tag is comprised of a microchip containing

identifying information and an antenna that transmits this data wirelessly to a

reader. The RFID chip will contain a serialized identifier, or license plate

number, that uniquely identifies that item, similar to the bar codes system. A

key difference, however is that RFID tags have a higher data capacity than

their bar code counterparts. An RFID tag can be placed on individual items, cases or pallets for identification purposes, as well as on fixed

assets such as trailers, containers, totes, etc.

Radio frequency identification Reader

(RFID Reader)

|

FIG 1.3 RFID READER

|

RFID reader is a device used to gather information from an RFID tag, which is used to track individual objects. Radio waves are used to transfer data from the tag to a reader. RFID is a technology similar in theory to bar codes. However, the RFID tag does not have to be scanned directly, nor does it require line-of-sight to a reader. The RFID tag it must be within the range of an RFID reader, which ranges from 3 to 300 feet, in order to be read. RFID technology allows several items to be quickly scanned and enables fast identification of a particular product, even when it is surrounded by several other items. RFID technology uses digital data in an RFID tag, which is made up of integrated circuits containing a tiny antenna for transferring information to an RFID transceiver. The majority of RFID tags contain at least an integrated circuit for modulating and demodulating radio frequency and an antenna for transmitting and receiving signals. Frequency ranges vary from low frequencies of 125 to 134 kHz and 140 to 148.5 kHz, and high frequencies of 850 to 950 MHz and 2.4 to 2.5 GHz. Wavelengths in the 2.4 GHz range are limited because they can be absorbed by water.

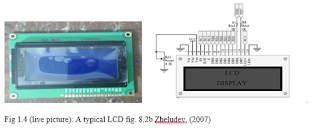

Liquid

Crystal Display (LCD):

Liquid crystal

display is the technology used for displays in notebook and

other smaller computers. Like light-emitting diode (LED) and gas-plasma

technologies, LCDs allow

displays to be much thinner than cathode ray tube (CRT) technology. The

display unit consists of a 2*16 Liquid crystal display (LCD). This feature

enables the status of the system to be viewed on a screen, making the system

user friendly.

|

| Fig 1.4 (live picture): A typical LCD fig. 8.2b Zheludev, (2007) |

The

model described here is for its low price and great capabilities most

frequently used in practice. It is based on the HD44780 microcontroller (Hitachi)

and can display messages in two lines with 16 characters each. It displays all

the letters of alphabet, Greek letters, punctuation marks, mathematical symbols

etc. In addition, it is possible to display symbols made up by the user. Other

useful features include automatic message shift (left and right), cursor

appearance, LED backlight etc.

TRANSFORMER:

|

| FIG 1.5 TRANSFORMER |

A

transformer is an electrical device that transfers electrical energy between

two or more circuits through electromagnetic induction.

Regulator

7805:

|

| Regulator 7805: |

Regulator is a device for controlling the rate

of working of machinery or for controlling fluid flow, in particular a handle

controlling the supply of steam to the cylinders of a steam engine.

JUMPER

WIRE:

|

| FIG 1.6 JUMPER WIRE |

IC

SOCKET (16 PIN and 40 PIN):

|

| IC SOCKET (16 PIN and 40 PIN) |

An

IC socket, or integrated circuit socket, is used in

devices that contain an integrated

circuit. An IC socket is

used as a placeholder for IC

chips and is used in order to allow safe removal and insertion

of IC chips because IC chips may become damaged from heat

due to soldering.

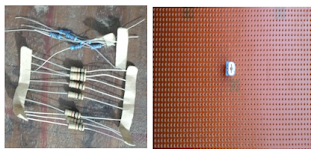

Resistors:

|

| Resistors |

Resistor is a passive

two-terminal electrical component that implements electrical resistance as a

circuit element. Resistors may

be used to reduce current flow, and, at the same time, may act to lower voltage

levels within circuits.

Capacitor

|

| Capacitor |

Capacitor

is a device used to store an electric charge, consisting of one or more pairs

of conductors separated by an insulator.

Crystals Oscillator:

|

| Crystals Oscillator |

A

crystal oscillator is an

electronic oscillator circuit

that uses the mechanical resonance of a vibrating crystal of piezoelectric material to create an electrical signal

with a precise frequency. Oscillator circuit is

constructed between 18 and 19 th pin of the controller. It includes an

oscillator of 11.0592 MHz and two capacitors of 33pF

RIBBON

CABLE:

|

| RIBBON CABLE |

Ribbon

cable is also known as multi-wire planar cable, is a cable with many conducting

wires running parallel to each other on the same flat plane.

RESET

BUTTON

|

| RESET BUTTON |

The 9th pin

of microcontroller is configured as RST pin, known as reset pin. It include a

switch, a capacitor and a resistor of 8.2k ohm. When switch is pressed RST pin

gets connected to vcc and the controller gets reset.

VERO BOARD

|

VERO BOARD

|

A Vero board is expertly constructed using strips of copper

clad on a top quality board featuring a grid pattern of holes spaced 0.1"

(or 2.54mm) apart. This design allows you to solder almost any non-surface

mount ICs, resistors, capacitors onto the Vero board. With the Vero board you

will receive both versatility and durability allowing you the freedom and

flexibility you crave!

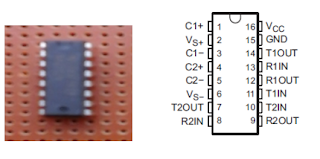

MAX 232

|

Fig: physical component of max 232 and Pin configuration

of MAX232

|

The

MAX232 is an integrated circuit that converts signals from an RS-232 serial

port to signals suitable for use in TTL compatible digital logic circuits. The

MAX232 is a dual driver/receiver and typically converts the RX, TX, CTS and RTS

signals.

|

Table 4.2.2: Pin configuration of MAX232

|

CONNECTOR

|

| Connector |

Connector

is a device used to join electrical circuit and are also referred to as

electrical connector

4.3

Output Design

The

final output of the embedded system to be developed is the basically on the attendance

by swipe or flashing the RFID Tag on the RFID Reader, to register the RFID tag

which transmit to the LCD displayed and also on the host memory platform.

|

| Output Design 1 |

And

after registering the RFID tag on the platform it will display on the LCD, for

example the student named Ayogu Vivian

has registered and her attendance as be recorded in the host memory

platform.

|

| Output Design 2 |

CHAPTER FIVE

SYSTEM IMPLEMENTATION

The

aim of this section is to describe the overall Implementation of the Radio frequency identification, thereby, helping the lecturers to manage their

student’s attendance systematically. The main objective is to automate the

whole system of student’s attendance registration using RFID. The system must

have database that contains student information and it must be able to help

lecturer to get accurate attendance of every student time to time. Based on the

attendance, a normal defaulters list and critical defaulters list will be generated

and a mail will be sent to the parents of critical defaulters. The interfaces

of the system are made very user friendly. With this system, students’ will

become more disciplined and punctual, as the time that they come to the class

will be recorded. As shown in Fig 2, the process begins when a student enters a

classroom he will place his card near the reader if he.

5.1

TESTING

The

system testing was done on proteus suite design

|

| system testing 1 |

|

| system testing 2 |

|

| system testing 3 |

CHAPTER SIX

CONCLUSION

6.1

Summary

A

recent development in technology allow many things to be done automatically and

this include the automation of attendance taking. The implementation of RFID in

attendance taking and the objectives stated on previous section has been

achieved. The RFID Based Attendance System able to store the student’s data in

the 89c51microcontroller’s EEPROM. The system can also uniquely identify the

students based on the assigned ID and name stored inside the microcontroller.

The process of tracking the absentees were also done properly by the microcontroller.

Input buttons were successfully implemented on RFID Based Attendance System.

The buttons provide the function to display the students entry stored on the

LCD Display and display the absentees’ data on the LCD. The system is portable

because the size is small and it provide two way power where adaptor power

supply can be replaced by battery to power up the circuit. The portability of

the system allow it to be placed on every type of classroom.

6.2

Evaluation

We

had a limited amount of time for the completion of the design so as a result of

that the system was not connected a computer and also does not have a database. It can still be improved by creating a graphic user

interface (GUI) and also by connecting a CCTV camera to capture the students

picture.

6.3 Recommendations

Based

on the problem stated on the previous section, this part will explain a method

or improvement that can be made on the system in order to tackle the problems.

6.4

Problem Encountered

There

are several problems noticed in the development and design of RFID Based

Attendance System. The first one is that the RFID Reader used in the design

doesn’t support a long range scanning. Thus, students need to place his/her ID

near the RFID reader. This could be a problem if there are many students

attending a class because they have to take turn placing their card on the RFID reader.

The

database of the students are stored in PIC16F76A microcontroller’.. It is also

difficult to modify the data because the microcontroller need to be reprogrammed

in order to introduce new entry in the database. In RFID Based Attendance System,

lecturer still need to press a button to check the absentee. It may become a hassle

for the lecturer to check the students name on the LCD. Thus, some sort of long

range communication from the system to the lecturer need to be added.

6.5

Lesson Learnt

We learnt how to

solder electronics components, how to program using assembly language and how

to use to RFID technology in reading student attendance and in identifying

object.

REFERENCES

Abdul Aziz Mohammed and Jyothi Kameswari, (2013)

Web-Server based Student

Attendance System using RFID Technology, International Journal of

Engineering Trends and

Technology (IJETT)–Volume 4 Issue 5.

Arulogun O. T., Olatunbosun,

A., Fakolujo O. A., and Olaniyi, O. M.,(2013) RFID-

Based Students Attendance

Management System International Journal of

Scientific & Engineering Research Volume 4, Issue 2.

Domdouzis K., Kumar B., and Anumba C.(2007) Radio- Frequency Identification

(RFID) applications:

A brief introduction, Advanced Engineering

Informatics,

Vol.21.

Ezekwe C. (2016).Completed

artificial intelligent assignment3 pp.95-191, awka Anambra

state.

Ezekwe chinwe, Ndinechi Michael, Okwu Patrick (2012). System

Architecture and

programming

Onitsha: B. fine

Ezekwe ,C. (2016). Class management system

using RFID awka Anambra State.

Lim T.S., Sim S.C. and Mansor M.M.(2009). RFID Based Attendance

System, in

Proceedings of the IEEE Symposium

on

Industrial Electronics and

Applications.

Sumita Nainan, Romin Parekh

and Tanvi Shah (2013). RFID Technology Based Attendance Management System International Journal of Information and

Computation Technology. ISSN 0974-2239 Volume 3, pp. 131-138© International Research Publications House

http://www. irphouse.com /ijict.htm\

Weis S. A., Sarma, S. E. Rivest R. L., and D. W. Engels. (2003). Security and

Privacy Aspects of Low-Cost Radio frequency identification Systems.

Security in Pervasive Computing.

Yeop Sabri M. K., Abdul Aziz M. Z. A., Mohd Shah M. S. R., and

Abd Kadir M. F

(2007). Smart Attendance

System by

Using

RFID,

Asia

Pacific

Conference on Applied Electromagnetic Pro

APPENDIX

CODES WRITTEN IN ASSMBLY LANGUAGE

ORG 00H

RS BIT p3.3

EN BIT p3.4

SWITCH1 BIT p3.1

SWITCH2 BIT p3.2

RFID_SIGNA BIT P3.0

LINE1 EQU 80H

LINE2 EQU 0C0H

LCD_DATA EQU P2

;MOV p3,#00h

CALL INIT_LCD

;...........................................................

DISPLAY:CALL

INITIAL_MSG_1

CALL

WR_DATA1

CALL

WAIT

SWIPE: CALL

INITIAL_MSG_2

CALL

WR_DATA1

RFID_SIGNAL:MOV TMOD,#20H ;timer 1,mode 2(auto reload)

MOV TH1,#-3 ;9600 baud rate

MOV

SCON,#50H ;8-bit, 1 stop, REN enabled

SETB

TR1 ;start timer 1

KEEP_CHECKN:JNB RI,KEEP_CHECKN ;wait for signal to

come in

CALL

OPEN_DOOR

JMP

SWIPE

;...........................................................

OPEN_DOOR:

CALL

MSG_OPEN

CALL

WR_DATA1

CLR

SWITCH1;..............

SETB

SWITCH2;.............OPEN DOOR PLS

CALL

WAIT

CLR

SWITCH1

CLR

SWITCH2

CALL

WAIT1

CALL

MSG_CLOSE

CALL

WR_DATA1

SETB

SWITCH1;...............

CLR

SWITCH2;................CLOSE DOOR PLS

CALL

WAIT1

CLR

SWITCH1

RET

;..........................................................

wr_instr:CLR RS

MOV LCD_DATA,a

SETB EN

call delay5ms

CLR EN

RET

wr_data:SETB RS

mov

LCD_DATA,a

SETB

EN

call

delay5ms

CLR

EN

RET

INIT_LCD:mov a,#30h

mov a,#38h

call wr_instr

mov a,#0ch

call wr_instr

mov a,#06h

call wr_instr

mov a,#01h

call wr_instr

ret

display_letter: call wr_data

ret

INITIAL_MSG_1:

mov

dptr,#dm_1

mov

r0,#30h

call

mov_next

mov

dptr, #dm_2

mov

r0,#40h

call

mov_next

ret

INITIAL_MSG_2:

mov

dptr,#dm_11

mov

r0,#30h

call

mov_next

mov

dptr, #dm_22

mov

r0,#40h

call

mov_next

ret

MSG_OPEN:mov dptr,#dm_3

mov

r0,#30h

call

mov_next

mov

dptr, #dm_4

mov

r0,#40h

call

mov_next

ret

MSG_CLOSE:mov dptr,#dm_5

mov

r0,#30h

call

mov_next

mov

dptr, #dm_6

mov

r0,#40h

call

mov_next

ret

attemt:

CALL

MSG_OPEN

CALL

WR_DATA1

CLR

SWITCH1;..............

SETB

SWITCH2;.............OPEN DOOR PLS

CALL

WAIT

CLR

SWITCH1

CLR

SWITCH2

CALL

WAIT1

CALL

MSG_CLOSE

CALL

WR_DATA1

SETB

SWITCH1;...............

CLR

SWITCH2;................CLOSE DOOR PLS

CALL

WAIT1

CLR

SWITCH1

RET

dm_1:db' SWIPE

CARD TO #'

dm_2:db'

REGISTER.. #'

dm_3:db'RFID_BASED DOOR #'

dm_4:db'RFID ATTENDANCE #'

dm_5:db'TRY 3 TIMES OR D#'

dm_6:db'RIGHT CARD..... #'

dm_11:db'WAITN FOR VALID #'

dm_22:db'RFID CARD SWIPE #'

dm_12:db' YOU ARE WELCOM #'

dm_23:db'ENAKPOBIA ESTHER#'

dm_14:db' YOU ARE WELCOM #'

dm_24:db'AYOGU VIVIAN .A.#'

mov_next: clr a

movc

a,@a+dptr

mov

@r0, a

inc

r0

inc

dptr

cjne

A,#'#',mov_next

ret

Wr_data1:mov A,#LINE1

call

wr_instr

call

delay5ms

mov

r0, #30h

wr_data1_:call display_data

cjne

r0,#3fh, wr_data1_

mov

a,#LINE2

call

wr_instr

call

delay5ms

mov

r0,#40h

wr_data2:call display_data

cjne

r0,#4fh, wr_data2

ret

display_data:mov a,@r0

call

wr_data

inc

r0

ret

delay5ms:mov r2,#13

mov r1,#34;244

jmp delay1

delay1ms:mov r2,#3

mov r1,#147

jmp delay1

delays: mov r2,#39

mov

r1,#200;229

delay1:djnz r1,delay1

djnz

r2, delay1

ret

WAIT: mov

r3,#36

mov

r2,#40

mov

r1,#176

waita: djnz

r1,waita

djnz

r2,waita

djnz

r3,waita

ret

WAIT1: mov

r3,#36

mov

r2,#40

mov

r1,#176

waita11:djnz r1,waita11

djnz

r2,waita11

djnz

r3,waita11

ret

END

7 Comments

good morning sir, i love your project design and its well explanatory but please can u illustrate or show how to connect all the components together with the vero baord. maybe with an illustrative flow sketch diagram. thank for taking your time to do this

ReplyDeleteThanks ridwan afolabi all the information you need is clearly provided in the above carefully go through it.

DeleteVery impressive blog with good content and project design.

ReplyDeleteThanks for posting this informative blog with us. Attendance Management Softwarefor more click here

Thanks do us good by following our blog and sharing our blog posts with your friends.

DeleteYour post is very good, Thanks so much for your post, Keep Posting.

ReplyDeleteSAFEALL ADP & VDP In Delhi

Thanks Safeall do us good by following our blog and sharing our blog posts with your friends.

DeleteThanks epunch timedo us good by following our blog and sharing our blog posts with your friends.

ReplyDelete